Chief Investigators

Dr Tim Lau (Adelaide University)

Purpose of project

Given the heating, ventilation, air-conditioning and refrigeration (HVAC-R) sector is a significant contributor to electricity consumption and peak electricity demand, often consuming up to 70% of customers’ electricity usage and about 24% of Australia’s electricity production, new approaches and technologies are required to improve the energy efficiency of refrigeration.

In this project, a new-generation, energy-efficient indirect evaporative (dew point) carbon dioxide (DP-CO2) refrigeration system was designed and installed at a Coles supermarket in Adelaide, South Australia. The DP-CO2 system uses 12 Seeley International CW-15S dew point (indirect evaporative) coolers to pre-cool the ambient air, which is then supplied to the gas coolers to provide the required heat rejection for the entire refrigeration system. Importantly, the project also involved monitoring the DP-CO2 system using over 100 different sensors across an 8 month period to provide detailed data on the performance, reliability and viability of this technology in real-world conditions.

Additionally, the team also developed a detailed computational model of the DP-CO2 system, and validated this model using the monitored data. This model uses a range of sub-models, including sub-models for the dew point coolers and the CO2 refrigeration system, together with the ambient weather conditions and the expected refrigeration loads, to predict the thermodynamic details, energy consumption and water consumption of the DP-CO2 system as a function of time. The model was then used to compare the energy consumption of the Coles DP-CO2 system with that of a more conventional spray-type adiabatically cooled CO2 refrigeration system.

The model was also used to estimate the performance of the DP-CO2 system in different sectors and across different climates, namely a hospital kitchen cool room in Brisbane, hospital HVAC in NSW (Tamworth, Griffith and Hornsby, Sydney), a sub-tropical aquarium, agricultural cold storage (apples), a brewery and a typical meat processing plant at representative sites around Australia.

Findings

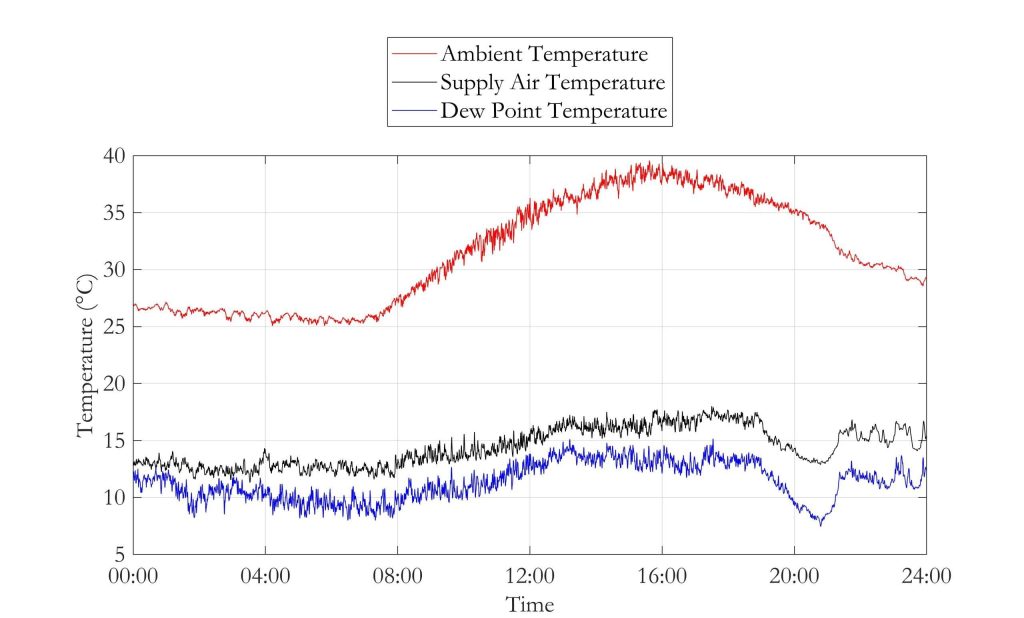

The DP-CO2 system performed strongly. Based on the 8 month monitoring period between July 2023 and February 2024, the system was able to deliver cool 17°C temperature supply air to the gas coolers despite the ambient temperature exceeding 40°C, which significantly reduced refrigeration energy consumption. The average difference between the ambient air temperature and the air temperature supplied to the gas coolers was 9.8°C and the supply air temperature was narrowly distributed between 5°C and 22°C. Importantly, the supply air temperature was below 20°C for 98.4% of the time, allowing the system to operate in the (more efficient) sub-critical mode most of the time.

Figure 1 Ambient and supply air temperatures for the installed system at Coles. Data was taken from the 23rd of January, 2024.

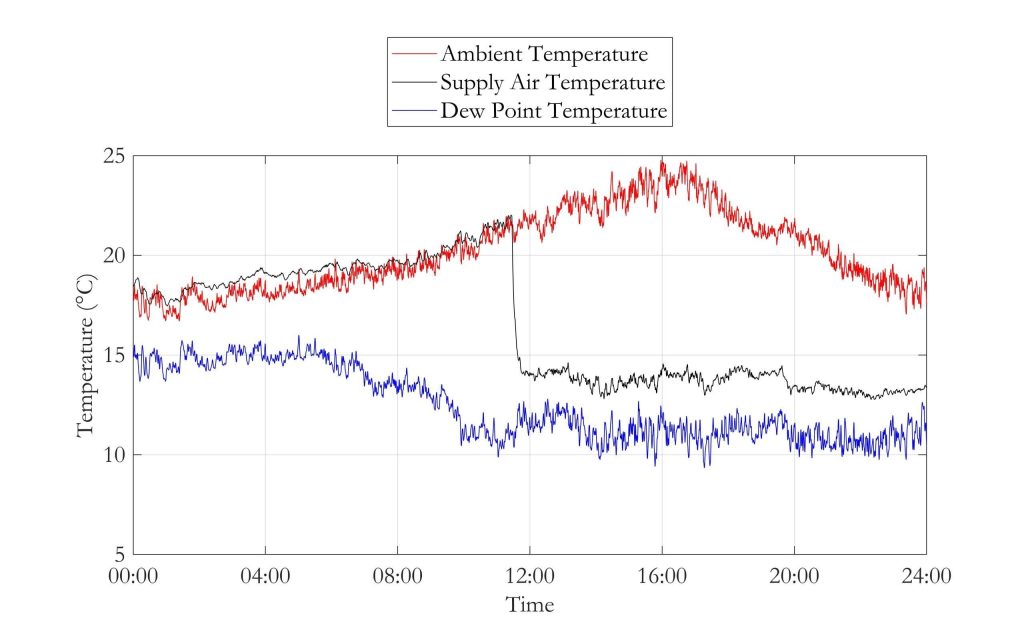

Figure 2 Air temperatures across the dew point cooler for DP-CO2 system installed at Coles. Data taken from the 26th of January, 2024, where the dew point coolers are turned off overnight (black line), and only turned on when the ambient conditions exceeded 20oC (at approximately 11 am).

The supply air temperatures closely matched the ambient dew point temperature (see also Figures 1 and 2), which implies that the DP-CO2 system is most effective in climates where the dew point temperatures are typically low (ie low humidity climates).

Both the DP-CO2 system and the monitoring system functioned as expected, albeit with a few minor issues, including a sub-optimal placement of the ambient temperature sensor too close to the dew point cooler outlets (which resulted in errors in the ambient temperature reading), and the sub-optimal selection of an approach temperature for the gas cooler outlets. Additionally, it was found that the original changeover procedures between the flash gas bypass mode and the parallel compression mode was sub-optimal, resulting in slightly lower system efficiencies. These issues have been rectified and are covered in Section 6 of the final report.

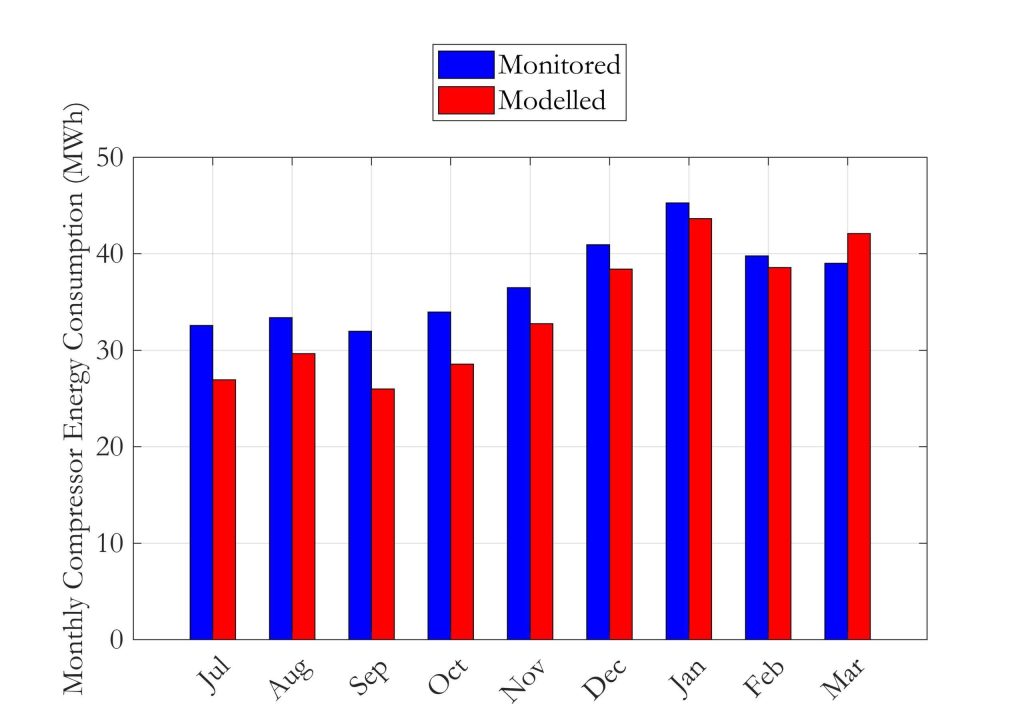

When the model was validated against measured CO2 refrigeration data, the DP-CO2 compressor energy consumption predicted by the model matched the monitored data from the Coles system to within 7% for the 8 months monitored as indicated in Figure 3, but as the project was terminated early, it was not possible to provide details for an entire calendar year as it missed February – June.

Figure 3 – Modelled vs monitored electrical consumption for the Coles DP-CO2 refrigeration system.

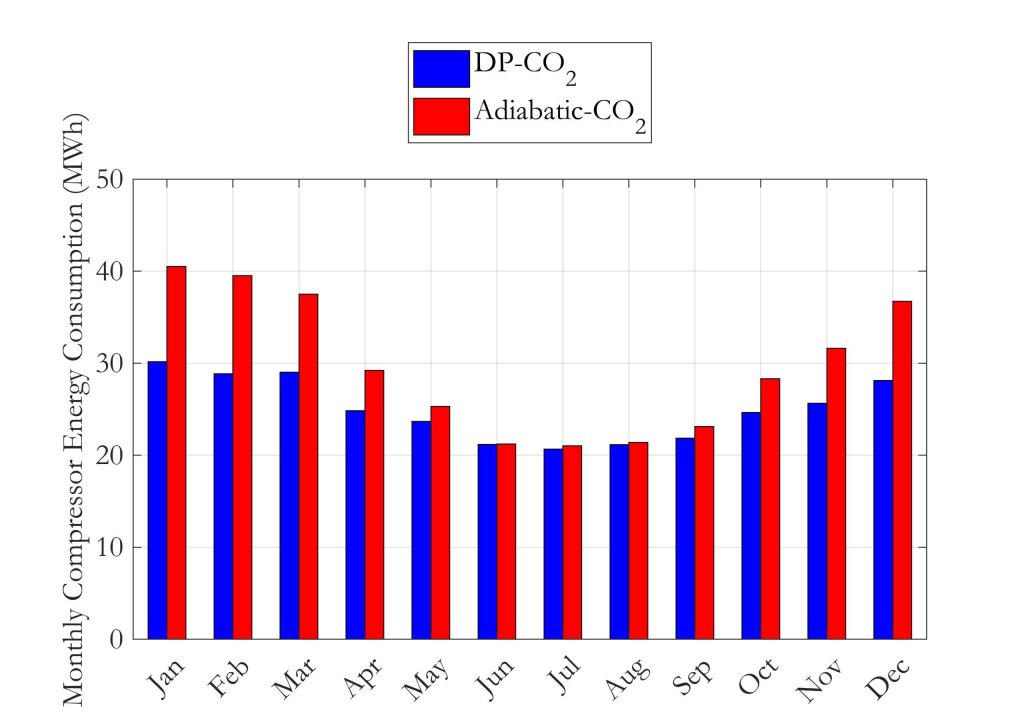

When the Coles DP-CO2 system was compared to a conventional spray-type adiabatically cooled CO2 refrigeration system, the results for a typical meteorological year in Adelaide show that the DP-CO2 system reduces energy consumption by 19.6% across the whole year, with the greatest reduction in energy consumption occurring in summer, where a 37% reduction is predicted, as indicated in Figure 4.

Figure 4 Modelled monthly energy consumption for DP-CO2 and adiabatically-cooled CO2 systems. The values here are for the current Coles system, under Adelaide weather conditions.

When the model was used to estimate the performance of the DP-CO2 system in different sectors and across different climates, the results showed that for a typical hospital kitchen cool room in Brisbane, the DP-CO2 system can reduce energy consumption due to refrigeration by 20-25% during the summer months compared to a conventional R134a system. However, the DP-CO2 system is less efficient in the cooler months, such that the total energy consumption across the whole year is approximately equal for both systems.

When the model was applied to a typical meat processing plant, with the location varied to represent sites all across Australia, the results showed that the DP-CO2 system reduced energy consumption by 4-27%, depending on location, compared to a conventional adiabatic CO2 refrigeration system. The most significant reduction occurs in hot, dry climates, such as those found in central and western Australia.

Impact of project

The project is expected to improve refrigeration system efficiency by 20% and reduce peak demand by 37%, which will reduce greenhouse gas emissions and ongoing operational costs for the host site. Coles and other HVAC-R owners may be encouraged to adopt this new generation DP-CO2 refrigeration system, thereby reducing electricity consumption, peak electricity demand and the greenhouse gas emissions associated with cold chains.

Project partners – industry and research

Adelaide University (Lead), Australian Alliance for Energy Productivity (A2EP), Queensland University of Technology (QUT), Seeley International

Industry Reference Group members

Alfa Laval, Americold, Australian Institute of Refrigeration, Air conditioning and Heating (AIRAH), Australian Meat Processor Corporation (AMPC), Coca-Cola Europacific Partners, Dairy Australia, Health Infrastructure NSW, Mater Health Services, Refrigerated Warehouse & Transport Association of Australia Ltd

Published Report

Status

- Completed

Project Leaders

- Tim Lau, Adelaide University

Related Articles

Completion Date

July 2024

Project Code

0233