Chief Investigators

Prof. Frank Bruno (Adelaide University)

Purpose of project

Heating Ventilation Air-conditioning Cooling and Refrigeration (HVAC-R) uses over 22% of Australia’s electricity and is a key contributor to peak electricity demand, when renewable energy generation is often not available. Using thermal energy storage to improve the flexibility of HVAC-R can potentially help reduce the electricity network peak demand by decoupling final energy consumption from peak periods, rather than chemical energy storage systems (ESS) such as batteries.

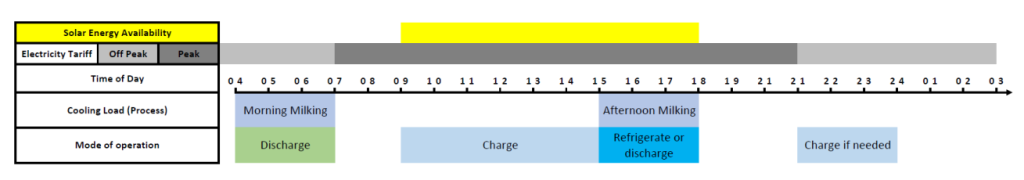

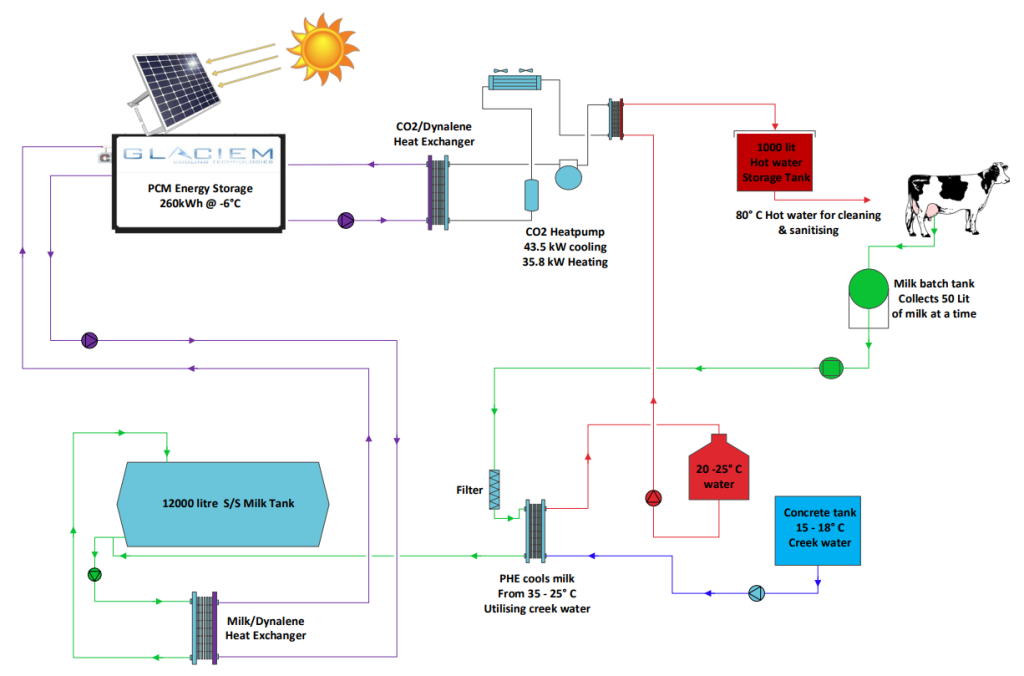

An EES can be charged when cheap, renewable electricity from solar photovoltaics (PV) is available, and then used later in the day during periods of peak electricity demand (summer days from 2.30-8.30pm). Phase Change Material (PCM) EES systems involve a secondary heat transfer fluid (HTF) to link the PCM EES and HVAC-R system, which adds complexity to the system, additional costs and limits suitable industrial applications. This project undertook a techno-economic assessment of interfacing solar PV with a PCM EES and refrigeration system, where both use carbon dioxide (CO2) as the HTF, at a dairy farm in South Australia (which required cooling and hot water for cleaning) compared to a conventional system using Dynalene/ CO2 and grid electricity.

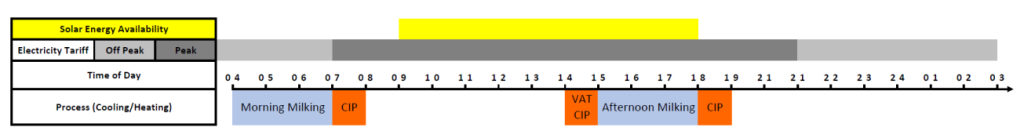

Figure 1: Daily milking schedule and milking/equipment wash down schedule at Misty Downs Dairy, South Australia

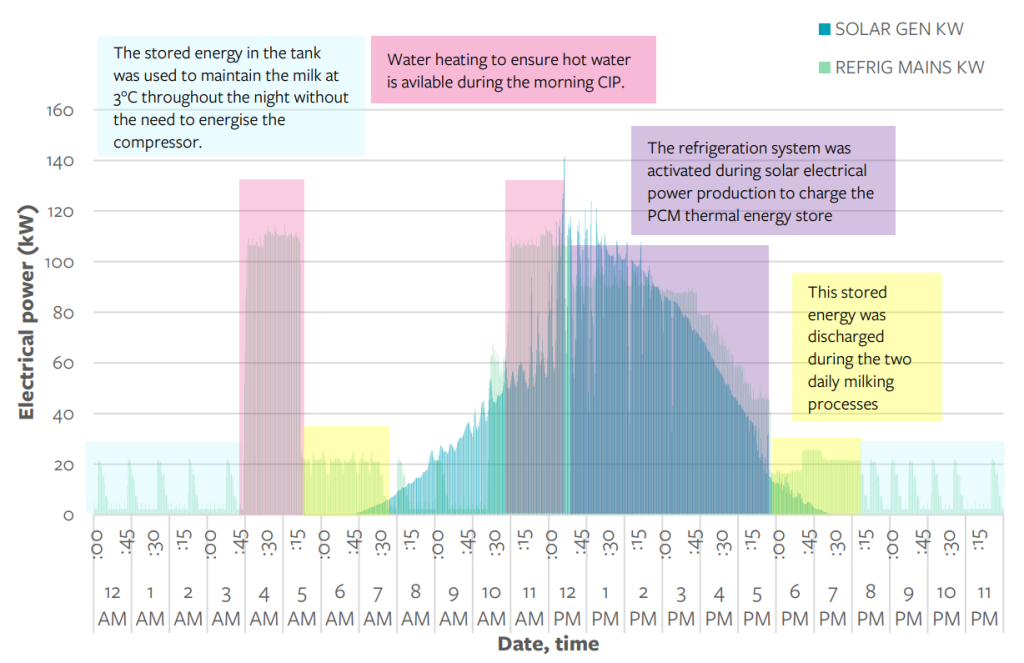

Figure 2: Typical daily electricity consumption in refrigeration vs solar PV electricity production based on data for 13 October 2020

Figure 3: Overall layout of the milk cooling plant at Misty Downs Dairy, with conventional Dynalene/CO2 HTF circuits

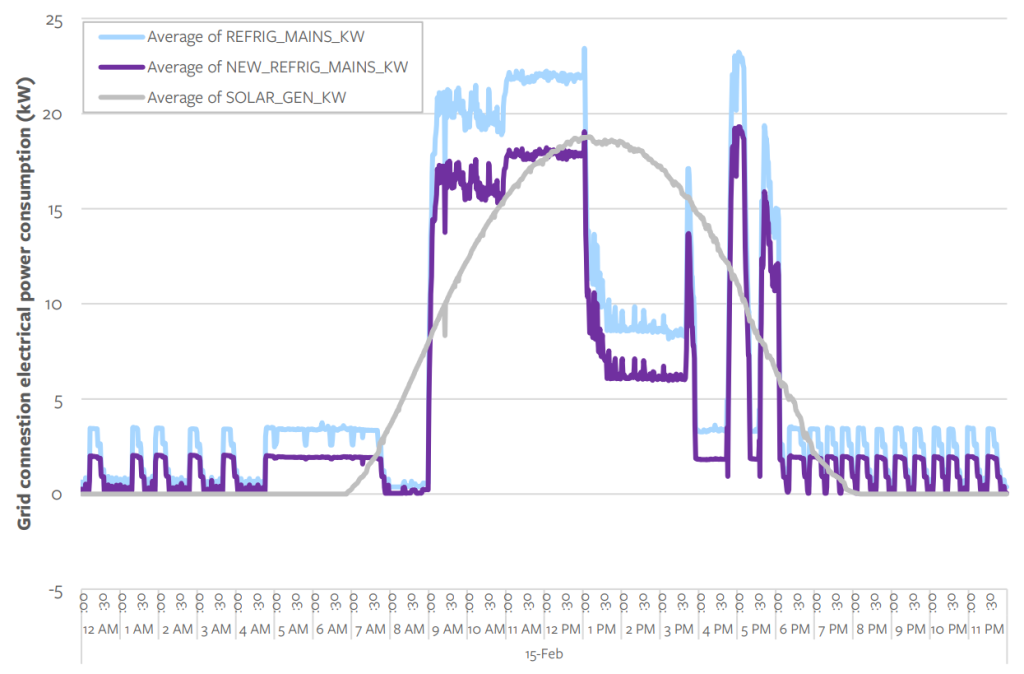

Figure 4: Electricity consumption comparison of original (Dynalene/CO2, blue) vs new (dual CO2, purple) system based on data for 15 February 2021

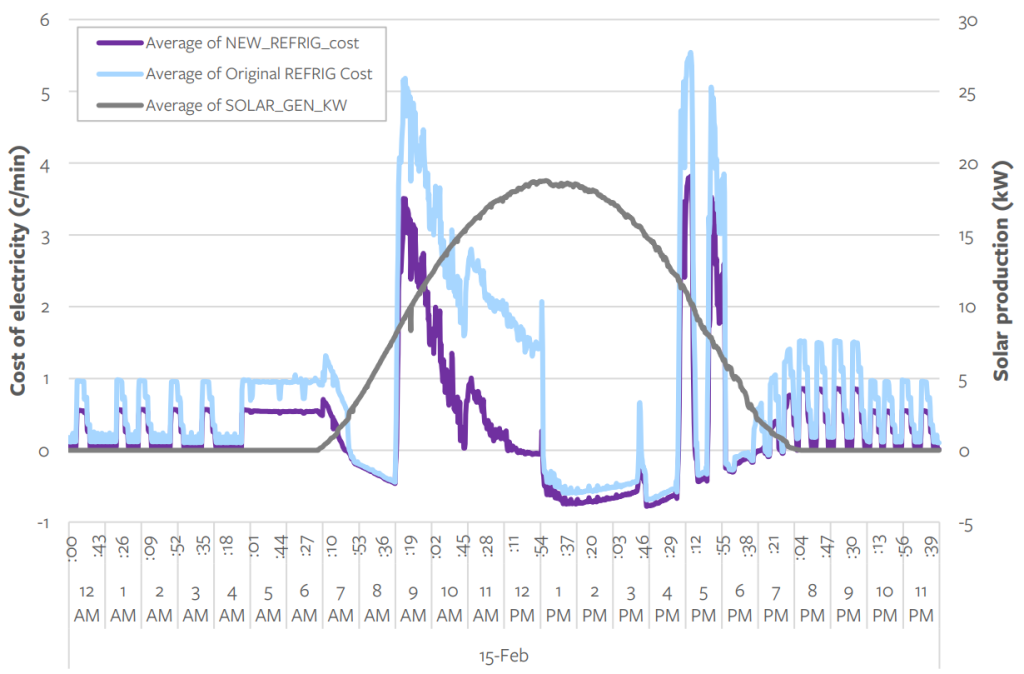

Figure 5: Power cost comparison of original (Dynalene/CO2, blue) vs new (dual CO2, purple) system based on data for 15 February 2021

Findings

- The pumping energy required to charge and discharge/use a PCM ESS is significantly lower when CO2 is used as the HTF for both systems, and the system achieves a higher heat transfer rate which results in a higher coefficient of performance for the refrigeration system

- A 26% reduction in electricity consumption was found, resulting in a 41% saving in energy costs compared to the conventional PCM EES system using Dynalene/CO2. The reduction in electrical cost was greater in summer months, as the increased solar PV output was able to provide all the electricity required for the refrigeration system

- Increased cost of the PCM ESS system with CO2 was 5% above the conventional Dynalene/ CO2 system, but the annual savings gave a payback period of 1.1 years

- Ability to store energy provided security from electricity grid interruptions increased the quality of the milk

- The greenhouse gas saving which results from reduced grid electricity consumption during peak periods will depend on a range of factors, such as the greenhouse gas intensity of the grid electricity and the degree of curtailment of any onsite solar PV electricity produced.

Potential impact

This project will help increase the network hosting capacity for renewable energy and reduce electricity costs for all customers, given the 26% reduction in electricity consumption. It means that sites can cost effectively convert electricity generated from solar PV onsite into stored thermal energy which can then be used during peak electricity demand periods.

Research roadmap – the path to decarbonisation

PCM ESS technology is potentially suitable for any site that has a combination of onsite solar PV and HVAC-R, such as wineries, food processing and supermarkets. The economic assessment of this site indicated that the project had a 1-year payback based on the energy saving alone, although the economics may vary for other sectors depending on the electricity load profile and ability to shift load from the peak demand period.

Project partners – industry and research

Adelaide University (lead), Australian Alliance for Energy Productivity, Glaciem Cooling Technologies (technology provider), RMIT

Published Report

Status

- Completed

Project Leaders

- Frank Bruno, Adelaide University

Completion Date

April 2022

Project Code

0133