Chief Investigators

Prof. Frank Bruno (UniSA)

Purpose of project

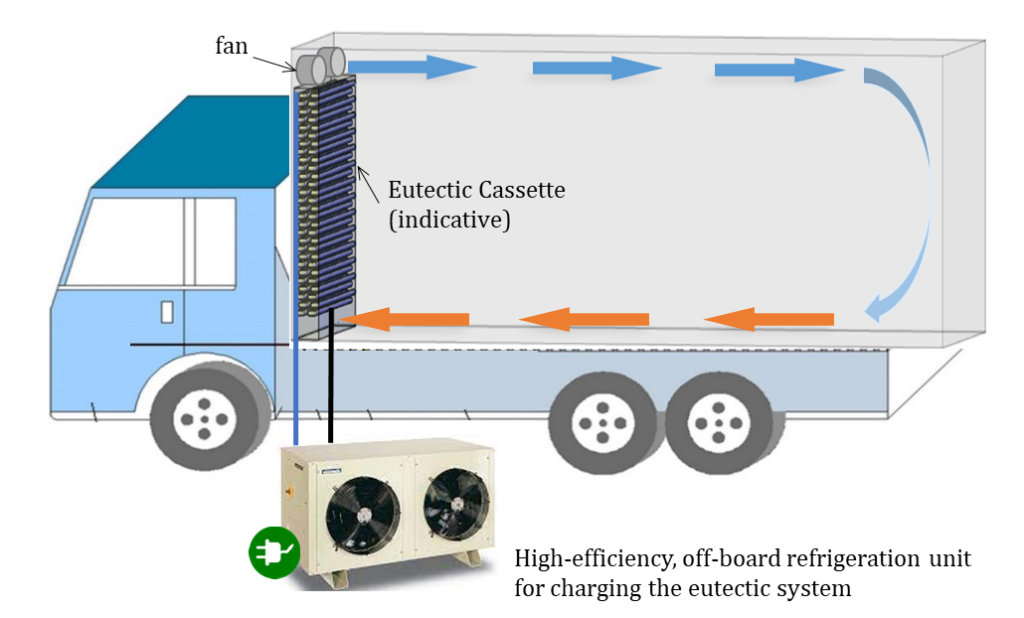

Refrigerated transport plays a key role in cold chain logistics. The project reviewed state-of-the-art and emerging refrigeration systems used in commercial transport and developed a concept design for a eutectic refrigeration system suitable for use in both diesel and electric light to medium refrigerated transport vehicles for fresh and frozen produce delivery. The four systems reviewed included diesel and battery powered vapour compression refrigeration (VCR) systems, and eutectic refrigeration systems employing phase change materials (PCM) charged by off– and on-board electricity refrigeration systems. The use of advanced temperature monitoring and airflow control should ensure the system maintains a stable temperature efficiently, thus reducing food spoilage and waste.

Findings

- For a medium sized vehicle, greenhouse gas emissions from the refrigeration system could be reduced by 70% if the system is charged by grid electricity in South Australia compared to the diesel fuelled refrigeration system

- Eutectic refrigeration has the lowest energy consumption and operating costs compared to diesel-powered and battery-powered vapour compression refrigeration systems for transport, due in part to the higher performance of the charging refrigeration unit overnight

Figure 1: Schematic diagram of a eutectic refrigeration system charged by an off-board electricity refrigeration unit

Potential impact

Transport refrigeration systems are currently dominated by diesel-driven mechanical vapour compression systems with R404A refrigerant, which has a global warming potential of 3,922. Due to the variation in operating conditions, mobile refrigeration systems have very low coefficient of performance (0.5 – 1.75). These systems are estimated to consume 70-90 million litres of diesel annually in Australia, so fuel switching from diesel to renewable electricity has the potential to assist with cold chain decarbonisation efforts.

Research roadmap – the path to decarbonisation

- A prototype of the proposed system will be constructed and demonstrated in Adelaide

- The weight of the eutectic system is higher, and the impact on the vehicle fuel consumption will be tested in the next phase of the project

- The coefficient of performance of the system and the temperature control during use will be compared with the modelling used

- A charging schedule will be developed to manage the electricity demand and minimise costs

Project partners – industry and research

UniSA (Lead), Aldom, Department of Energy and Mining (South Australia), Simble

Industry Reference Group members

Australian Alliance for Energy Productivity (A2EP), Delvic Foods, Massey University, Queensland Farmers Federation, SuperCool Group, Mondial Advisory

Webinar recording

Published Report

Status

- Completed

Project Leaders

- Frank Bruno, UniSA

Completion Date

March 2023

Project Code

0203