Chief Investigators

Dr Michael Evans (Adelaide University)

Purpose of project

The primary focus of this Opportunity Assessment was to review and analyse new and existing technologies to decarbonise process heating needs for low temperature (below 150°C) heat, categorised by industry and process. The project reviewed opportunities for displacing fossil-fuels in the production of low temperature process heat through electrification and/or alternative renewable technologies.

Findings

- Major sectors requiring heat below 150°C include manufacturing (alumina, wood, paper), food processing (meat, dairy, beverages) and building (hospitality, residential aged care and hospitals). Together these sectors consume 180 PJ per year, which is 24% of all industry heating.

- Cost of heat delivery is lowest with renewable energy and energy efficiency, then thermal energy storage, while the costs are highest using green fuels. Renewable energy solutions include solar photovoltaics with heat pump/mechanical vapour recompression or electric boilers, solar thermal, biogas/biomass combustion combined with thermal storage. Green fuels include biogas upgrading toe biomethane, green diesel and hydrogen.

- Best practice energy efficiency requires immediate attention.

- Barriers to achieving the potential for accelerated heat decarbonisation are substantial, and include technical, non-technical, regulatory and commercial barriers. Technical issues include integration issues and impacts on the electricity grid, in addition to a lack of quality data on heating processes. Non-technical issues include a lack of skills, knowledge, tools, training and cultural factors. Regulatory issues include a lack of regulation and a lack of understanding about how current regulations will affect technology uptake. Commercia barriers include costs and commercial constraints.

Potential impact

If this project is successful, it is expected to lead to widespread update of process heating alternatives. For instance, displacing current technology for existing processes between 100-150°C (accounting for ~20PJ/year) with heat pumps could cut business energy bills by at least $24 million/year.

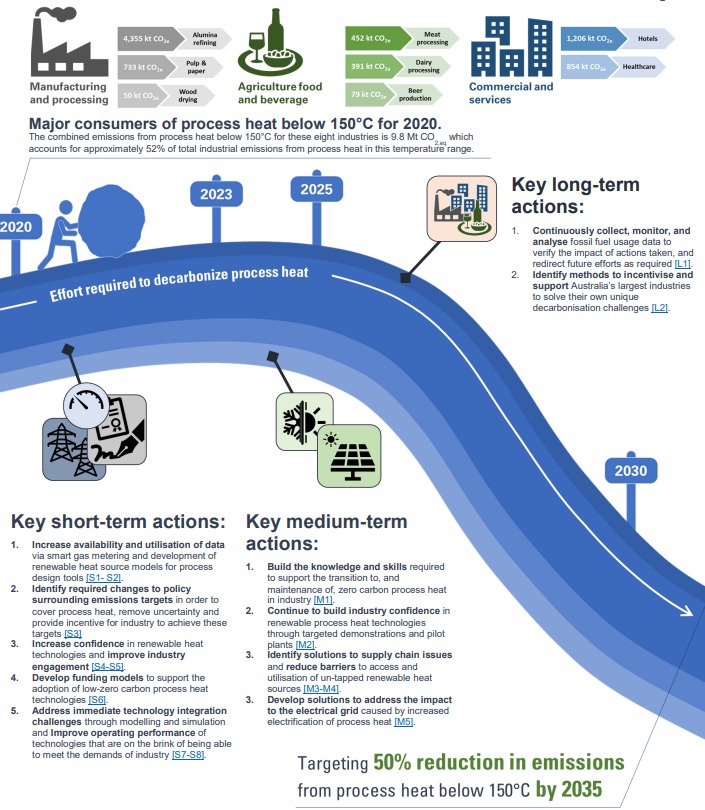

Research roadmap – the path to decarbonisation

The diagram below provides an overview of research needs for decarbonising heating and includes short, medium and long term actions.

Project partners – industry and research

Adelaide University (Lead), Australian Alliance for Energy Productivity (A2EP), Alfa Laval, Australian Meat Processor Corporation (AMPC), Climate-KIC Australia, Glaciem Cooling Technologies, QUT, RMIT, UTS

Industry Reference Group members

AGL, Australian Renewable Energy Agency (ARENA), Beyond Zero Emissions, Bright Brewery, Energetics, Energy AE, Greenlands Systems Solar, Northmore Gordon, RayGen, Rocky Mountain Institute, Saputo, Simble, Sunovate, Sustainability Victoria, Sydney Water, University of Waikato, Veolia, Visy

Published Report

Status

- Completed

Opportunity Assessment

- Completed

Project Leaders

- Michael Evans, Adelaide University

Completion Date

August 2021

Project Code

0121