Chief Investigators

A/Prof. Prasad Kaparaju (Griffith University)

Purpose of project

This project assessed the techno-economic feasibility of biogas production from sugar mills, such as bagasse, trash and mill mud from Mossman Sugar Mill, codigested with other organic wastes, such as chicken manure, food and banana waste. Anaerobic digestion (AD) was performed in laboratory studies for individual substrates and combinations, to optimise the biogas production. The methane yields were then used to design and complete an assessment of a full-scale biogas plant.

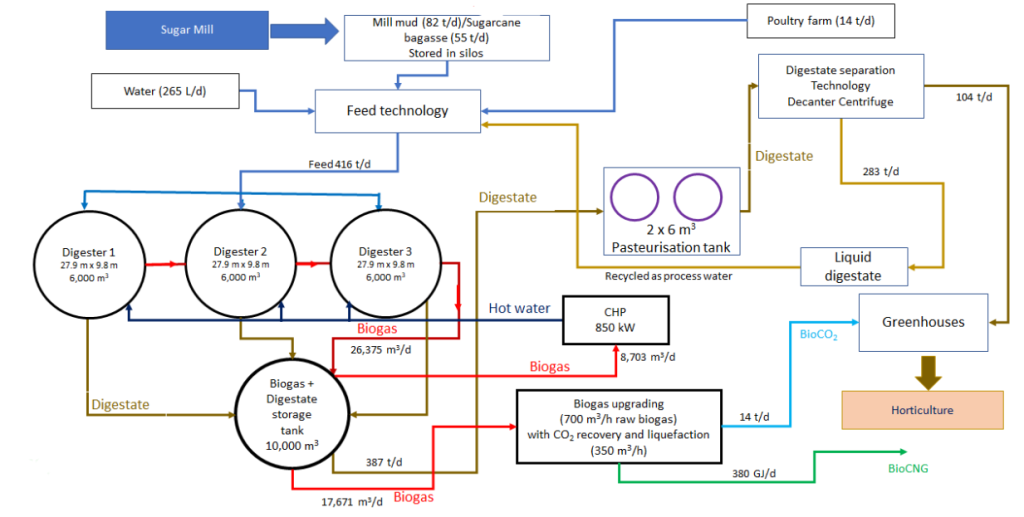

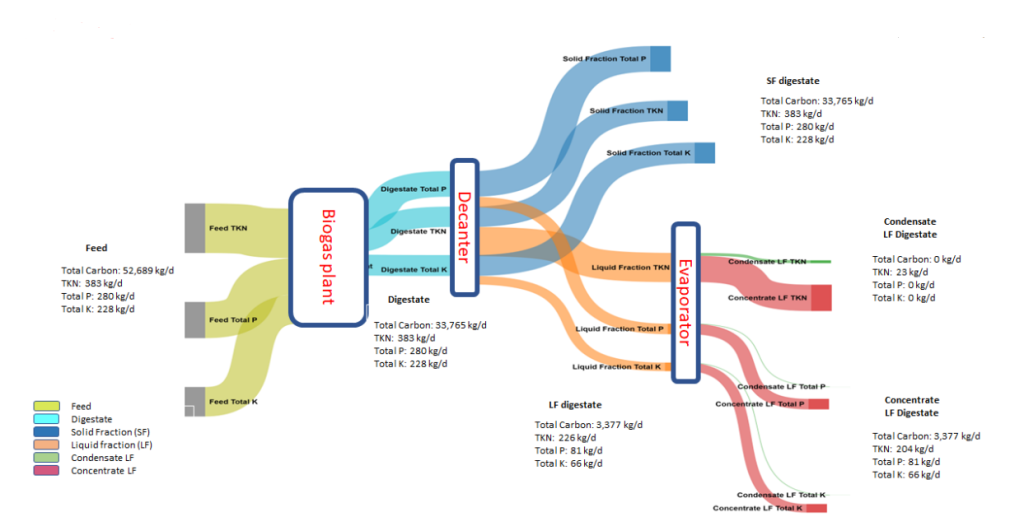

Three scenarios were evaluated for the economic viability of the project, using biogas for electricity and heat generation in a cogeneration/combined heat and power plant with the sale of excess electricity to the grid (Scenario 1), upgrading biogas to compressed biomethane (BioCNG) (Scenario 2, refer to Figure 1) and upgrading biogas for grid injection (BioRNG) (Scenario 3). In the latter two scenarios, the biogas production was first used to meet the plant energy demands, then the remaining biogas available for BioCNG/BioRNG use. The carbon dioxide stream generated from the biogas upgrading process was recovered and liquefied for sale (BioCO2). The nutrient-rich digestate from the biogas plant was separated into solid and liquid fractions, and the solid fraction was sold as fertiliser while the liquid fraction was recycled as process water. Mass, energy and greenhouse gas balances were analysed, including the avoided greenhouse gas emissions by replacing fossil fuels and inorganic fertiliser with their renewable, bio-equivalents (refer to Figure 2 for nutrient mass balance).

Findings

- The highest methane yields were obtained when sugarcane bagasse and mill mud were codigested with chicken manure and food waste, following by codigestion of sugarcane bagasse and mill mud with food waste or chicken manure.

- The lowest methane yields were obtained when sugarcane bagasse and mill mud were codigested together

- If 20,000 tonnes of sugarcane bagasse, 30,000 tonnes of mill mud and 5,000 tonnes of chicken manure annually were codigested in a biogas plant, it could generate 9.35 million Nm3 of biogas per year. The plant would be 2.2 MW in capacity, with 3 x 6,000 m3 digesters operating with an organic loading rate of 3.3 kg volatile solids/m3/day and hydraulic retention time (HRT) of 35 days under mesophilic conditions (37°C).

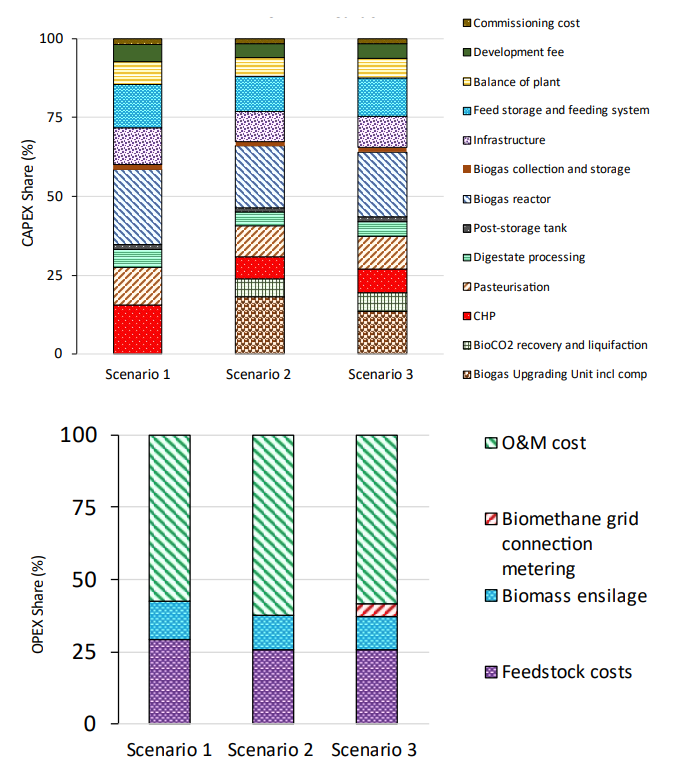

- Capital costs for a 2.2 MW plant were $20.4 million for scenario 1, $25.0 for Scenario 2 and $23.6 million for Scenario 3 (refer to Figure 3), with payback periods of 21, 10 and 15 years respectively

- Annual revenue from Australian Carbon Credit Units (ACCUs) and green certificates were $3.4 million, $5.3 million and $4.3 million for the 2.2 MW Scenarios 1, 2 and 3 respectively. This had a significant, positive impact of the return on investment (ROI).

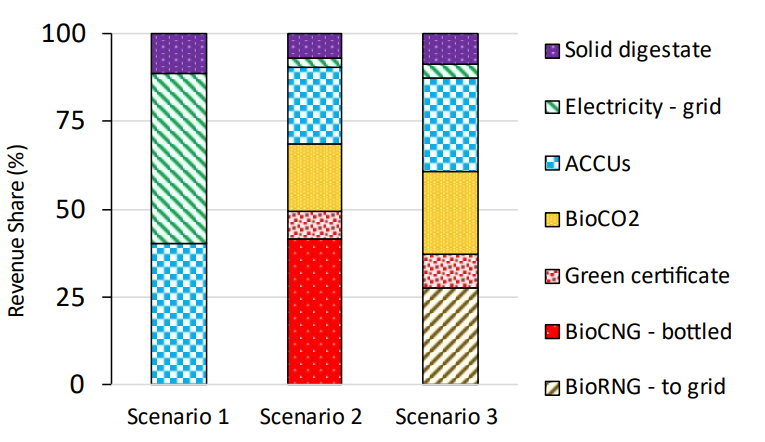

- Revenue breakdowns (refer to Figure 4) are discussed in more detail in the report. For Scenario 1, 48% of the revenue comes from the sale of electricity to the grid, with the remainder from the sale of solid digestate, while for Scenarios 2 and 3, sale of BioCNG/BioRNG and BioCO2 provides 60% of revenue

- Sensitivity analysis showed that the AD project is very sensitive to feedstock gate prices, feed-in tariffs and plant capacity. The minimum plant capacity should be 6.6 MW to be economically viable, with ROIs of 27-33%. A group of farms or mills could build a large-scale centralised biogas plant, similar to the Danish centralised biogas plant model

- The price of electricity dropped from $0.11/kWh in a 2.2 MW plant to $0.04/kWh in a 8.8 MW plant

- The estimated cost of BioCNG production decreased from $20/GJ in the smaller plant to $7/GJ in the larger plant

Figure 1: Process flowchart for Scenario 2 (biogas upgrading to BioCNG)

Figure 2: Nutrient mass balance for biogas plant

Figure 3: Capital and operating costs breakdown for the 3 biogas scenarios

Figure 4: Revenue breakdown for the 3 biogas scenarios

Potential impact

Australia is transitioning toward a clean energy economy. Biogas can play an important role by providing an opportunity to meet our renewable energy targets and decarbonise our economy, as well as provide a holistic solution to sugar industry and other livestock farms and municipalities in managing their wastes. The national biogas industry is likely to expand since there is significant potential for growth in feedstock, coupled with rising electricity prices and landfill gate fees.

This project will repurpose sugar industry wastes to reduce operating costs for Australian farmers, while helping them to transition to renewable energy and decarbonise their value chains.

Research roadmap – the path to decarbonisation

The study identified a number of barriers which need to be addressed and removed to allow projects such as this to be realised. Barriers to be addressed were the inclusion of agriculture in the Emission Reduction Fund, to allow ACCUs to be created for agriculture-based AD projects, inclusion of biomethane in the hydrogen Guarantee of Origin scheme and amending the National Greenhouse and Energy Reporting (NGER) scheme so that BioCNG and BioRNG end users can reduce their reportable emissions and certainty of substrate availability and composition.

Project partners – industry and research

Griffith University (Lead), Australian Alliance for Energy Productivity (A2EP), Helmont Energy, Queensland Farmers Federation (QFF), Singh Farming

Published Report

Status

- Completed

Project Leaders

- Prasad Kaparaju, Griffith University

Completion Date

March 2023

Project Code

0149